Главная

О нас

видео

Сервис

Свяжитесь с нами

- Печь для термообработки

- Плавильная печь

-

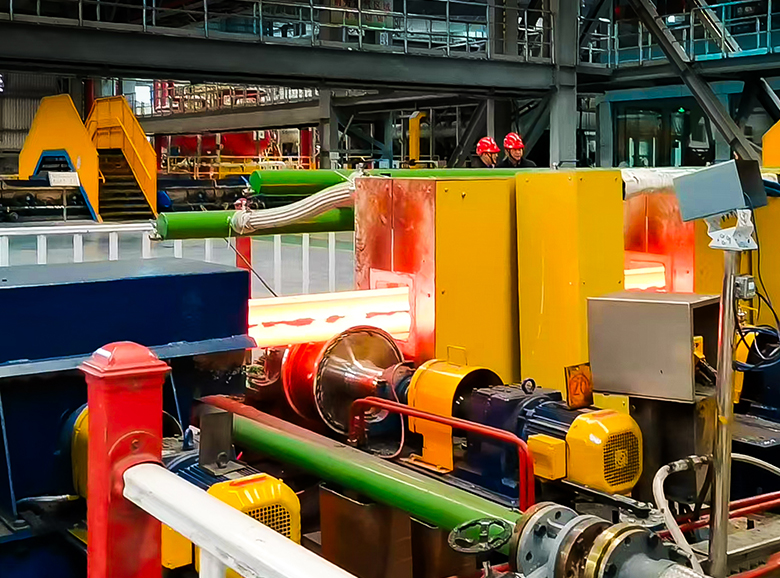

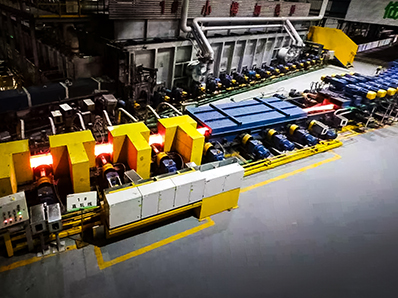

Прокатный стан

- Станок для прокатки ребристой арматуры

- Прокатный стан для катанки

- Стан для производства листовой стали

- Литейно-прокатный стан

- Алюминиевый стан холодной прокатки

- Медный стан холодной прокатки

- Сортовой прокатный стан

- Планетарный прокатный стан

- Машина непрерывного литья заготовок

- Линия непрерывного литья и прокатки алюминиевой катанки

- Литейное оборудование

- Принадлежности

+86-15036707993

+86-15036707993

+86-15036707993

+86-15036707993